| Fin Pattern | Corrugation | Characteristics | Common Uses | |

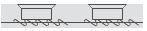

| Louvered |

|

|

Louvered fins increase the heat-transfer capacity by creating air turbulence which reduces the boundary layer on the fin's surface, but at a cost of increased air-pressure drop across the coil. |

|

|---|---|---|---|---|

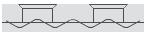

| Corrugated |

|

|

Corrugated fins improve the heat transfer factor to a lower degree than louvered fins. They also have a lower resistance to air flow. |

|

| Flat |

|

|

Flat fins reduce ice accumulation on fins. They have the lowest resistance to air flow. |

|